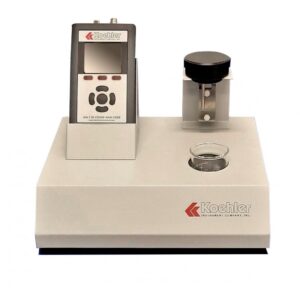

Automatic Cold Filter Plugging Point Analyzer with Touch Screen

$3,000.00

The cold filter plugging point detection system provides automated

sample testing with the accuracy and repeatability in accordance with

ASTM D6371 and related international test methods. The sample is

cooled according to the pre-selected temperature profile. A 20 mBar

vacuum is applied to the sample at specific intervals across a 45 micron

mesh filter into the aspiration glass cell assembly. If it takes more than

60 seconds for the sample to reach the upper barrier detector or more

than 60 seconds to return below the detector upon release, then the test

is complete and the cold filter plugging point has been reached.

s complete and the cold filter plugging point has been reached.

Integrated Panel PC and Software Package – The KLA Series of

analyzers are complete standalone systems featuring an integrated

panel PC with an advanced software package. The 12” TFT/LCD touch

screen display has a resolution of 1024×768 with a 16.2 M color scheme.

All analytical parameters are graphed and displayed in real time as well

as recorded in Microsoft® Excel compatible file format. The software

monitors the operation and performance of all the analyzer components

for proper data measurement, including the solenoid valves, cooling

system, pressure sensors, and the Platinum resistance PT100 Class A

temperature probe.

Cooling System – For various user applications, the automated

cold filter plugging point system comes standard with cooling for

temperatures as low as -95°C. The direct cooling system features

integrated gas CFC free motors compressors thus eliminating the need

for a solvent cooling bath. The direct system is capable of rapid cooling,

approaching -80°C bath temperatures in approximately 15 minutes, and

utilizes less electricity than standard cooling systems. The rapid cooling

feature combined with a consistent cooling profile system provides

repeatable results with high test reproducibility.

Vacuum System – The automated cold filter plugging point analyzer

includes an internal vacuum generator. The internal vacuum generator

provides a smaller footprint for the complete CFPP system and consists

of a 350 mBar micro-pump and an electronic pressure/vacuum

regulator composed of a proportional valve, pressure/vacuum control

sensor, regulator for reference vacuum generation at 20 mBar and a

vacuum stabilizer.

Multiple Configuration System –These automated sample cooling and

physical property measurement systems can be configured with one,

two, three, four and six test positions with one of five possible analytical

heads at each position: cloud point, pour point, cloud & pour point,

cold filter plugging point and freezing point. Standard and customized

multiple configuration systems are readily available.